Barry Bogs Union Pacific FEF-3 in 1/22.5 Scale

Barry Bogs Union Pacific FEF-3 in 1/22.5 Scale |

|

|

|

The Boiler -

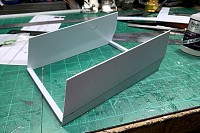

September 18th, 2022 The boys in the fabrication shop have been super busy with the boiler fabrication process. I sent one of the boys to Home Depot to get a section of 3 inch pipe and unions, as the basis to be able to fabricate the boiler. The boys wasted no time putting the pieces together to first form the smoke box with the couplings. They then started adding the rings around the tube to build up the boiler the the right size. The fire box panels were cut out and then added to the rear of the boiler, with the angle cut, for the back head area. Once all of the rings and fire box were attached, the guys then wrapped the boiler with a 20 thousand wrapper, and boiler bands were installed to cover over the seams and seal it up. Weight of the boiler has always been a concern, and in the past, I have directed the boys to fill the the area between the three inch tube and the wrapper with resin to make it solid, but I thought that I should try something with less weight. I got a can of spray foam insulation at HD again, thinking that it could be sprayed into the area instead of the resin. Well, it made a big mess on my test piece and I threw it away as a lesson well learned, then went back to the resin fill! Filling the voids took multiple pours, and on one pour, I started seeing resin flowing from the side of one of a boiler band! Again, another big mess to clean up! When are the boys going to double check the seals? Another lesson.... The boiler is heavier than what I would like, and it puts lots of stress on the chassis. The chassis has to bend to go around the curves on the railroad, so it is jointed between the second and third driver. The boiler is attached on the front between the cylinders with a single screw, and the frame was extended to the middle of the fire box area, and a small slot was cut in the frame for a screw holding the rear frame to the firebox. When the chassis bends, the distance between the front screw under the smoke box and the rear screw in the firebox area gets slightly shorter, thus the reason for the slot. With the heavy weight of the boiler sitting on the chassis, it is causing the flex joint between the drivers to want to bow up, so to keep the weight even across the chassis, I directed the boys to add a bearing block under the boiler, and let it ride on a plate attached to the chassis between drivers 2 and 3 where the joint is. When the boys tested it out, all of them came back smiling, so they must have done something right! Just another fun day in the shop.... - Barry |

|

|

|

|

|

|

|

switch to the progress photos in this series |

|

|

|

to the FEF-3 Project page | the C&W Home Page |

|