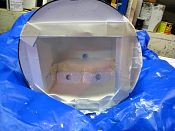

The F 3 Nose Casting

Barry created his own master, then mold, for the F3 nose.

< Slideshow > <

Return > to the F 3 photo section Created 1/22/09

Words from Barry on progress:

Above are

the F unit nose casting and molds. The mold cost well over $100 to make! I used

a piece of 8" stove pipe, so that it would fit in

my

pressure pot. I filled the master up with plaster on the back side of it and

placed it in the bottom of the pipe, with a piece of plastic glued

to the

bottom of the pipe, to seal it off. I then poured the rubber over the top of

the master and added some old, cut up molds, to it so that

I did not

have to use up as much new rubber. Once it set up, I pulled the master

out and reassembled the pipe, less the bottom around the

mold. I

poured a small amount of urethane on every face of the mold and so to build up

the thickness of what I wanted the castings to be.

It took

about 10 pours to get everything covered at the right thickness. I had to make

a make shift dam in the mold out of tape, to build up

the front

window areas. Once finished, I poured the inner mold, with a box in the center.

This box comes out and then I can collapse the

inner

mold and pull it out from the finished casting. I did not vacuum the inner mold

and it is filled with air pockets on the surface. I did not

want to

collapse the box in the middle and since it is on the inside of the casting, it

is no big deal if the casting is rough in that area.